Our Products

Heat Transfer Fusing Paper

Transfer papers function as a medium for printing. It's used mainly where printing is difficult on different surfaces. It's easier to print on Paper and then transfer the print to that surface. On transfer papers printing can be done by Silk Screen, Offset, Gravure, Flexography etc. First printing is done on the transfer papers. After which the printed image/matter is transferred to any surface like textiles, metals, ceramics, plastics, etc by application of heat. Heat can be applied by means of a heat press or an iron. Plastisol Ink is used and most people do it by screen printing.

More popularly called Textile Transfers or Heat transfers or 'T' shirt Transfers or Transfer fusing papers: for transfering the printed image (mainly by screen printing) by application of heat. For printing on fabrics,T-Shirts etc. Available both in reel and sheet form.

Silicone Coated Release Papers

Silicone coated release papers are used as backing for self adhesive (PSA) labels, stickers, bakery release, hygiene, tape industries, medical, graphics, and various industrial applications, in gaskets, water treatment plants, etc.

- We coat Silicone Release coatings on both Indian and Imported base paper in various GSMs.

- Base papers are Glassine, SCK, MGK, CCK etc.

- Coatings done by 3-roll and 5-roll differential release systems.

- Different types of Silicone Release coating available, solventless, solvented and emulsion systems etc

- Available in standard sheet sizes and roll forms.

- Different made to order types of sizes, both is sheet and reels subject to availability.

- Generally available GSMS are from 34-135 GSM.

- In Easy release to tight to very tight releases.

- Coated one side or both sides.

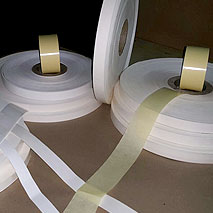

- TAPES OF RELEASE PAPERS, COATED ONE SIDE OR COATED BOTH SIDES are available on tailor made bases. Slit sizes of minimum 15 to 18mm and up are available.

Tatoo's Papers

for transfering the printed image to the human body like a tatoo.

- Available in sheets.

- Available in reels.

Fusing Paper for Textile Printing

This is used to fuse the printing done directly on the Textiles / Fabrics / 'T' shirts. Put the printed fabric area directly under our Fusing paper and under a heat press and fuse the print and remove our paper. Time and temperature is ink and fabric dependent. Note Printing cannot be done on these Fusing papers however some people are able to achieve the same.

- Available in both reel and sheets form. Small reels of 5-7-8kgs also available.

- GSMs available 80 to 100 GSM. Most popular is 90 / 95 GSM.

- Our "fusing" paper is different and it is not to be confused with the embroidery or backing paper.

Decals or Ceramic Transfers

for transfer printing on Ceramics or other surfaces.

- Available in sheets only.

- Can be made available in reels also.

Custome Coatings

Any specific coatings which can be done on our machines without any damage we can look into it.